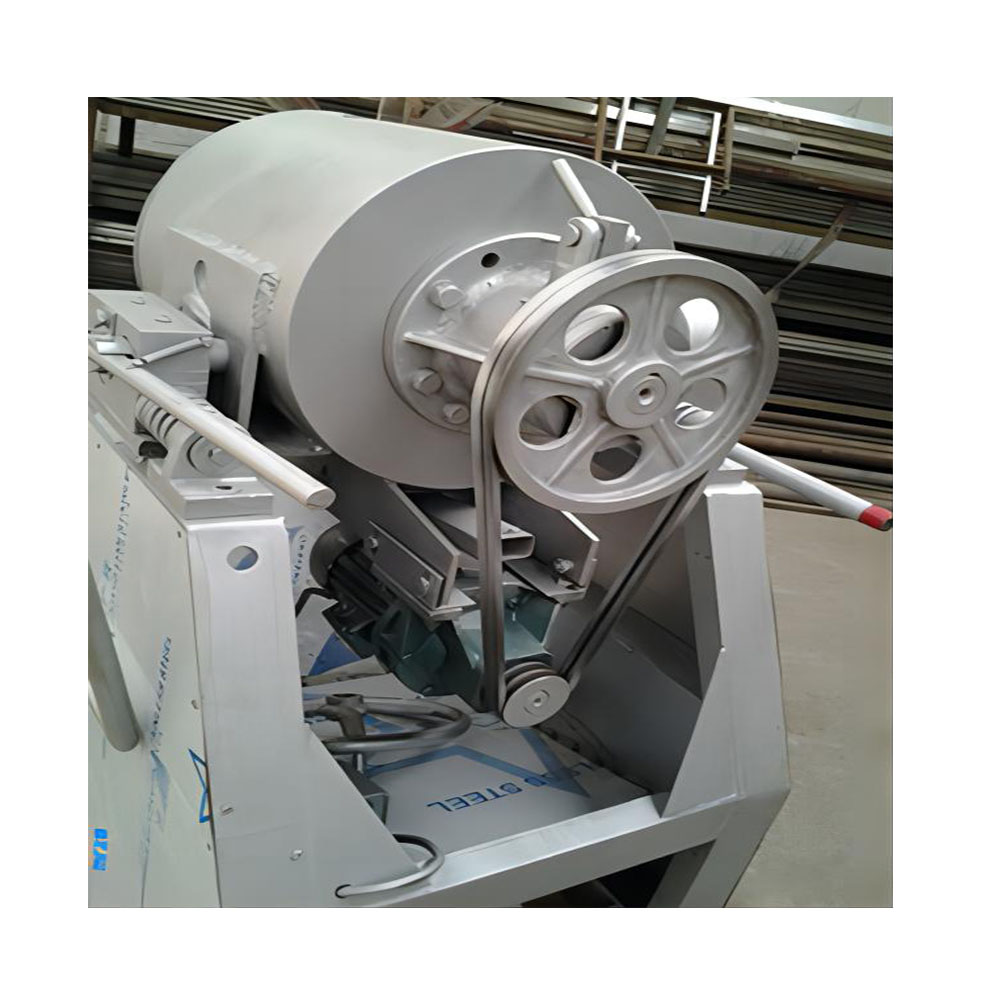

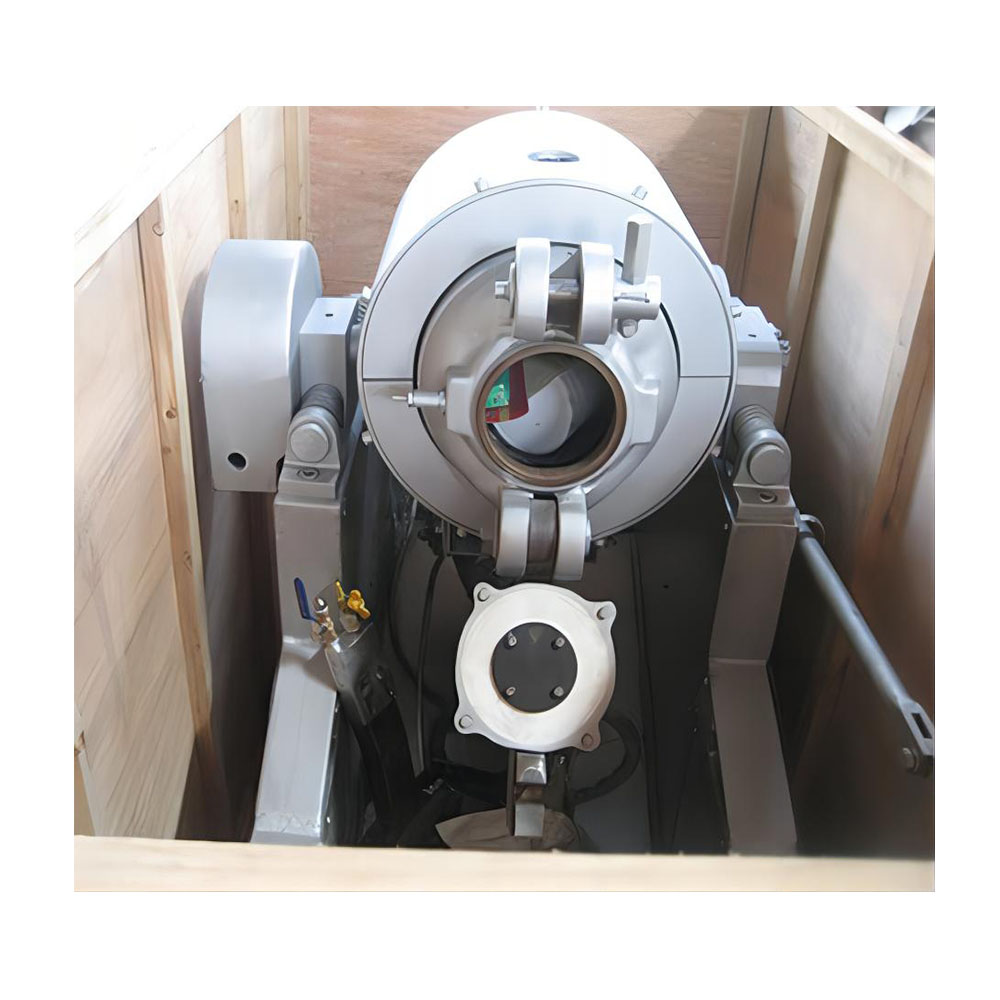

Air Flow Puffing Machine

We provide an extensive range of snack production solutions. Regardless of how unique your projects are, our professional expertise will deliver the optimal option tailored to your needs.

We provide an extensive range of snack production solutions. Regardless of how unique your projects are, our professional expertise will deliver the optimal option tailored to your needs.

Model | AFP-330 |

Capacity | 8-10KG |

Performance | 0.75KW |

Dimension | 1650*800*1350 |

Corn puffing machines operate by extruding corn kernels through a high-temperature, high-pressure environment inside the equipment; as the kernels exit the extruder, they expand and puff up. The shape of the puffed snacks can be customized by replacing the internal molds or dies of the machine.

Corn puffing machines can create multiple snack shapes—such as hollow, crossed, and solid balls, peanut-shaped snacks, and classic options like puffs and cheese balls. Adding flavors like cheese or spices allows for diversification of products.

Yes, there are small corn puffing machines that are suitable for small scale production and enable businesses or individuals to produce puffed snacks efficiently on a smaller scale.

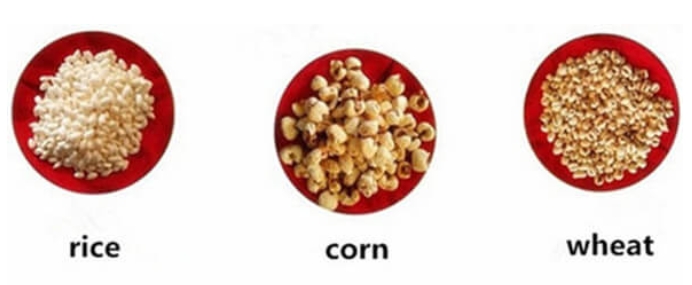

Designed to produce puffed corn snacks such as corn puffs and cheese balls, corn puffing machines take whole or crushed corn, rice, and other grains as raw materials, and produce diverse snack shapes through extrusion.