Mini Snack Machine

We provide a comprehensive range of snack production solutions. Whatever the nature of your project, our professional expertise ensures that we can offer the most suitable and effective solution for your specific needs.

We provide a comprehensive range of snack production solutions. Whatever the nature of your project, our professional expertise ensures that we can offer the most suitable and effective solution for your specific needs.

Developed using extensive industry experience and cutting-edge international technology.

Compact, lightweight, and easy to operate thanks to its simple and space-saving design.

Delivers high efficiency and low operating costs while ensuring excellent product quality and a much shorter processing cycle.

Compatible with multiple molds, enabling the production of puffed snacks in a variety of shapes and designs.

Safe food additives can be added to create a wide range of flavored puffed snacks using the mini puff snack machine.

This type of puffing machine can produce many kinds of puffed snacks with attractive shapes, such as hollow bars, peanut shapes, millet cookie flowers, hemp flowers, pentagrams, rectangles, mung bean shapes, diamonds, crispy rice shapes, matchbox shapes, and more.

Different flavored puffed snacks can be made by adding sodium cyclamate, salt, seasoning, or other food additives.

It is suitable for expanding snack food production lines, especially for puffed snack production.

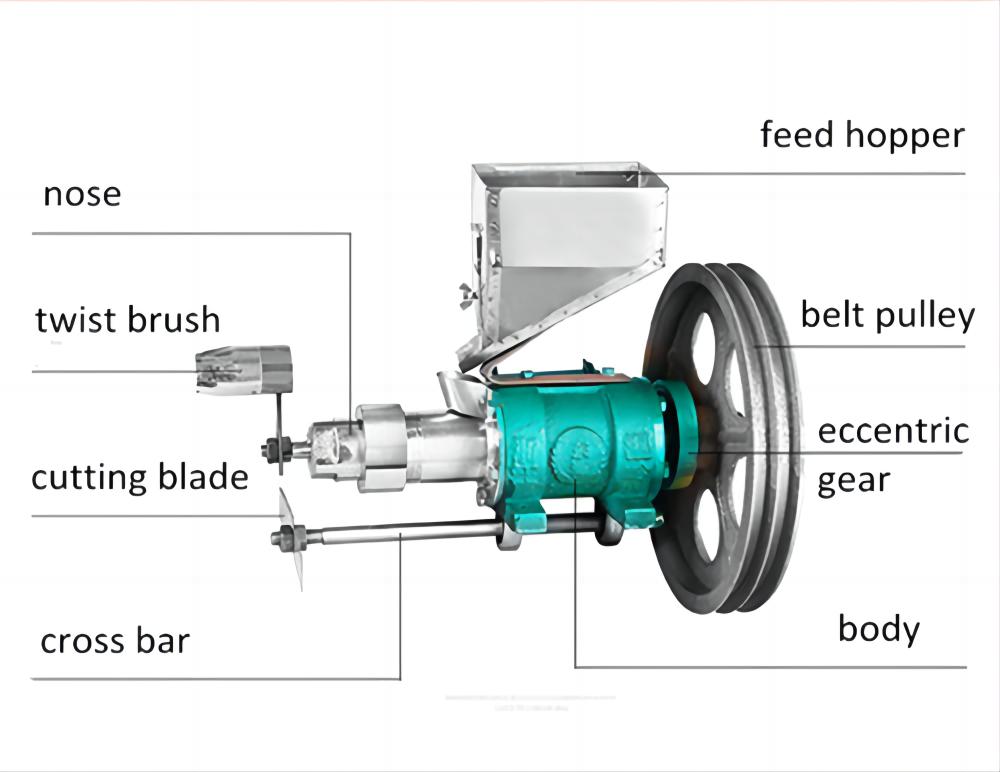

The mini puff snack machine is a versatile solution for processing corn, rice, sorghum, and other grains. It is capable of producing puffed snacks in three primary shapes — hollow bars, peanut shapes, and solid bars. By using different molds, it can also create a variety of additional shapes such as stars (pentagrams), rectangles, mung bean shapes, and matchbox shapes.

Thanks to its reliable performance and low investment cost, the puff snack extruder is an excellent choice for home use or small-scale snack businesses.

Model | C-007 |

Capacity | 50-100KG/H |

power | 3KW |

Using overly dry raw materials, allowing foreign objects to enter the screw groove, or uneven feeding may result in poorly formed products.

If the screw groove becomes blocked, do not shut down the machine immediately. Stop feeding first to reduce pressure and avoid damage.

After each operation, allow the machine to run for about 1 minute without feeding to ensure all remaining materials are fully discharged.

Disassemble and clean the machine carefully. Always wear protective gloves during disassembly to prevent burns.

Avoid feeding excessive material at once, as this can easily lead to clogging and affect production quality.

It’s suitable for producing puffed snacks made from corn, rice, and other grains, such as popcorn, corn balls, cereal rings, stick-shaped puffed snacks, and pet food. It’s ideal for small-scale start-up factories, prototype R&D centers, and food brands looking to test and prototype.

The Mini Snack Machine’s smaller size and simpler structure allow for flexible layout and low-cost start-up. Despite its compact size, it maintains high production capacity and stability, making it ideal as an entry-level production device or as a supplementary proofing machine for main production lines.

The Mini Snack Machine leverages proven thermal expansion and high-pressure extrusion technologies, combined with an energy-saving design, to achieve efficient, fast, and stable puffing. Its design references international standards for small-scale puffing equipment and is compatible with a wide range of ingredients and recipes.

The stainless steel hopper and extrusion chamber are easy to clean and meet food safety requirements.

The high-strength steel drive system ensures stable operation.

The lightweight body makes it easy to move and install.

All food contact parts comply with FDA and EU food contact material regulations.

Assuming a single machine produces six hours per day, easily covering the needs of one or two workers, the typical payback period for a startup customer is three to six months.

The entire unit is covered by a 12-month warranty, including a parts package and online and remote technical support. On-site installation and training are also available.